Fibre networks are silently powering today’s industrial revolution, from automated factories to remote diagnostics. Here’s a no‑BS guide to the basics of how they work and why they matter.

The Fibre Push

But all that shiny tech comes with one thing in common: it needs serious bandwidth. And the old copper networks that used to “just about do the job” can’t keep up anymore. They’re too slow, too short-range, and too prone to interference.

That’s why there’s a proper push now towards fibre installations. It’s faster, tougher, and built for the data-heavy, always-on demands of modern industrial sites. Fibre doesn’t just make things work, it keeps them working, without the bottlenecks.

A Whole Lot Smarter

In my opinion, factories were setup with stand-alone production lines and isolated machines. Everything worked in its own little corner, and copper cabling was fine with short runs, simple comms, and not much shouting between systems. Speeds were modest, and devices sat close together, so the 100-metre copper limit wasn’t really a problem.

But times have changed.

Now sites are pushing for full connectivity across the board—every PLC, sensor, camera, robot arm and kettle wants to talk to something else. Data’s flying across buildings, zones, and even off-site. And when you’ve got hundreds of devices trying to communicate across the entire site, copper just doesn’t stretch far enough.

Here’s the numbers bit:

Copper works well for short links. Up to 100 m, and usually maxes out at 1 Gbps

Fibre? We’re talking 10 Gbps and beyond, and it’ll happily run for kilometres without breaking a sweat.

So if you’re cabling up a modern factory or data-hungry warehouse, fibre’s not a luxury, it’s a necessity. It gives you speed, distance, and headroom for whatever comes next.

The Fibre Cable

Steel wire armour (SWA) loose tube fibre cable is commonly used in industrial sites. It can be suitable for outdoors, flame retardant, suitable for direct burial, suitable for harsh environments and rodent proof. Typically supplied in 4, 8, 12 or 24 cores. Usually supplied in OM3 or OM4 nowadays.

| Fibre Type | Core Size | Typical Jacket Colour | Supported Speeds | Max Distance (10 Gbps) | Notes |

|---|---|---|---|---|---|

| OM1 | 62.5 µm | Orange | Up to 1 Gbps | ~33 m | Legacy fibre, OK for older systems but not ideal for new installs |

| OM2 | 50 µm | Orange | Up to 10 Gbps | ~82 m | Still around, but limited for future upgrades |

| OM3 | 50 µm (laser-optimised) | Aqua | Up to 40 Gbps | ~300 m | Good for most modern networks—popular in data centres |

| OM4 | 50 µm (enhanced laser-optimised) | Aqua / Erika Violet | Up to 100 Gbps | ~400–550 m | High-performance and cost-effective—solid future-proofing |

There is also singlemode and multimode fibre.

Multimode = short runs, tight budgets, great inside buildings

Singlemode = long distances, high speeds, higher price tag

If you’re linking two cabinets 200 m apart in a warehouse, multimode will do. But if the fibre runs are site to site for example, singlemode is usually better.

Fibre Connector Types — What’s What?

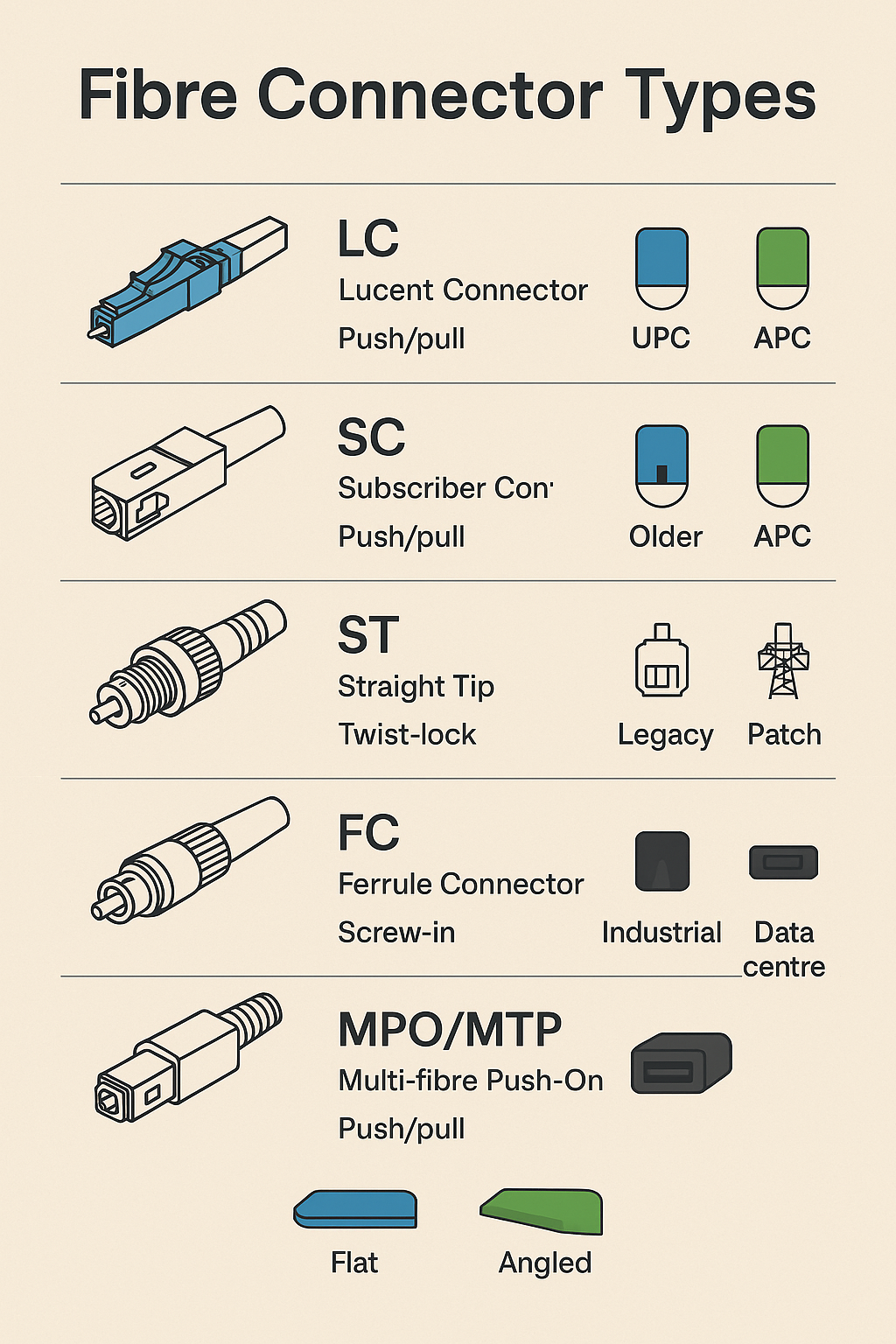

Fibre connectors can feel like someone is just saying letters. LC, SC, ST, FC—what’s the deal? Here’s a quick rundown of the main ones you’ll actually come across:

| Connector | What it Stands For | Type | Typical Use | Key Features |

|---|---|---|---|---|

| LC | Lucent Connector | Push/pull | Modern kit, SFP modules, patch panels | Tiny, compact—great for high-density installs (think switches & patch bays) |

| SC | Subscriber Connector | Push/pull | Older kit, FTTH, patch panels | Bigger than LC, but dead simple and still very common |

| ST | Straight Tip | Twist-lock | Legacy installs, CCTV, military | Round with bayonet fitting—was popular, now fading out |

| FC | Ferrule Connector | Screw-in | Industrial, high-vibration areas | Rugged and reliable—but slower to install and not as common anymore |

| MTP/MPO | Multi-fibre Push-On | Push/pull | Data centres, high-speed backbones | Handles 12, 24, even 48 fibres in one go—super high-density |

Figure A – Fibre Connector Types

Handy Tips:

LC is king on modern parts, especially in SFP ports on switches and media converters.

SC is still everywhere, especially in older or cheaper gear.

If you’re working in a dusty or high-vibration industrial site? FC connectors can be worth the hassle, they don’t shake loose.

ST looks cool and locks in tight, but don’t tend to see it often nowadays.

MPO/MTP = fibre on steroids. Never actually seen this on site.

Eejits Thoughts

We’re seeing fibre installs pop up everywhere these days. It’s not just for high-speed internet anymore, factories, data centres, and even smart buildings are using fibre to tie together all sorts of systems.

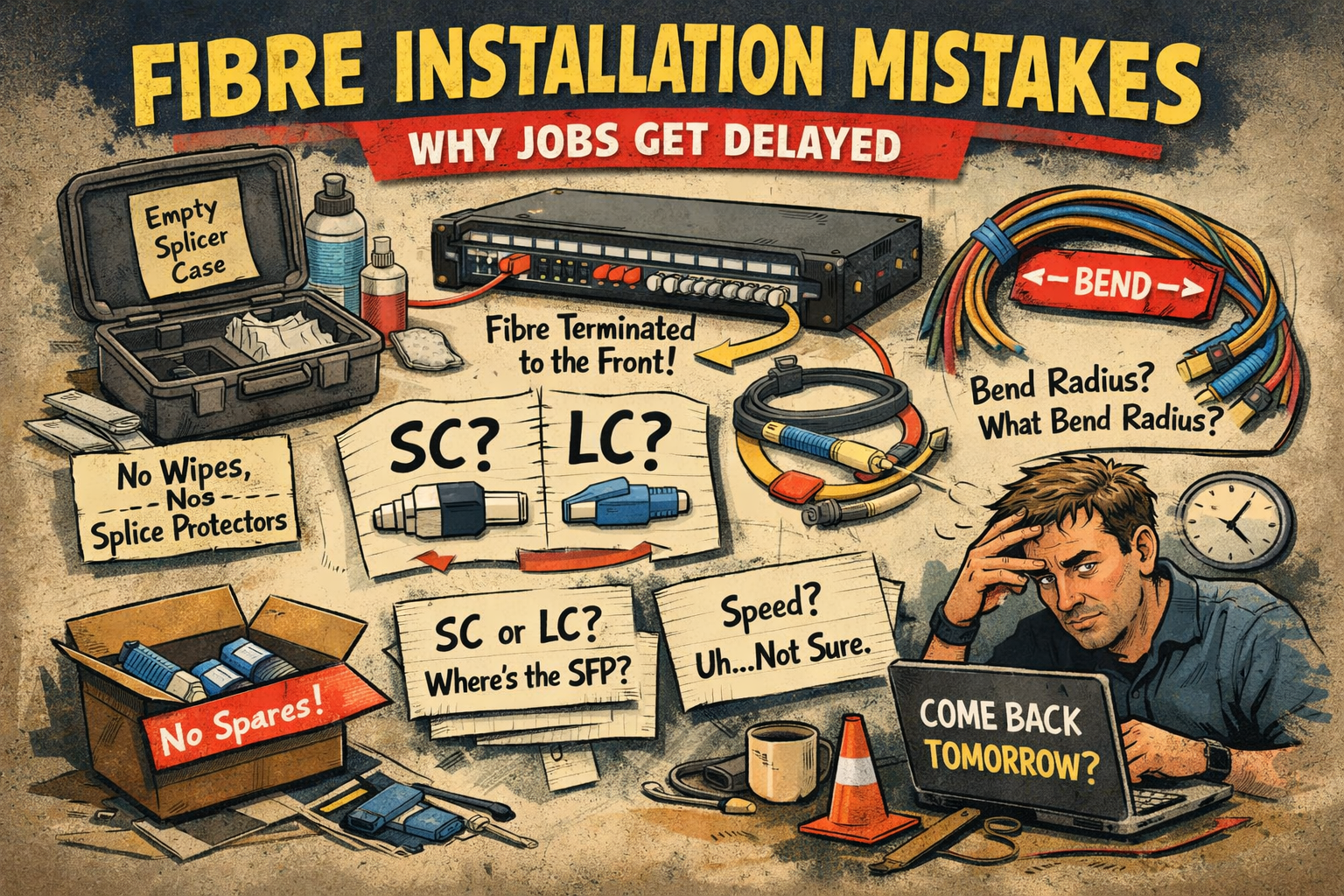

But it’s not always plug-and-play.

There are plenty of pitfalls, from ordering the wrong connectors to forgetting about proper containment routes. We’ll cover the common gotchas in a follow-up post.

For now, just know this: specifying the right parts at the beginning (cables, patch panels, SFPs, fibre types, etc.) can save you massive headaches later on. We’ll dive deeper into how to get that right in another article too.

Got a tricky fibre setup or story? Drop it in the comments

Leave a Reply